Why should factory equipment be fitted with an insulation jacket?

Energy saving and consumption reduction

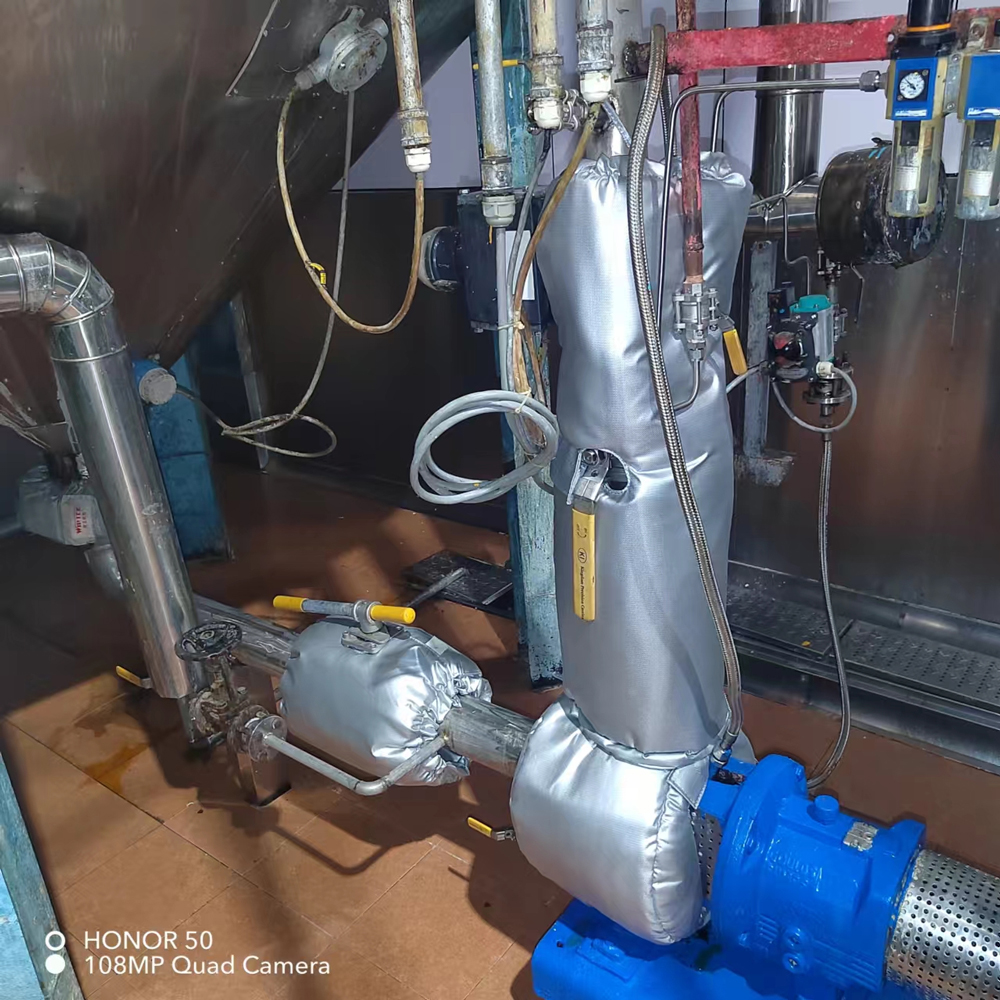

For pipelines and equipment in the industrial field, such as steam pipelines, reactors, etc., the Thermal Insulation Jacket can reduce the heat loss to the surrounding environment, keep the internal medium at the required temperature, reduce energy consumption, and save energy costs such as fuel or electricity. Steam piping, for example, not installed insulation, heat will be quickly emitted into the air, resulting in a large amount of heat waste, and after the installation of insulation, can effectively prevent heat conduction, improve energy efficiency.

?

?

protects equipment and pipelines

Insulation sleeve can reduce the thermal stress of equipment and pipelines due to temperature changes. For example, in some chemical equipment, drastic changes in temperature may lead to expansion or contraction of the equipment material, long-term will make the equipment cracks, deformation and other damage, the installation of Thermal Insulation Sleeve can make the equipment temperature to maintain a relatively stable, prolong the service life of the equipment.

?

?

Improvingtheworking environment

In industrial places, if the surface temperature of pipelines and equipment is too high, it will increase the temperature of the surrounding environment, resulting in a hot working environment, which affects the efficiency and comfort of workers, and may even be hazardous to their health. After installing the insulation sleeve, it can reduce the surface temperature of the equipment and improve the thermal comfort of the working environment.

?

?

Reduce the phenomenon of condensation: When the medium temperature inside the equipment is low, if the surface temperature of the equipment is lower than the dew point temperature of the surrounding air, the water vapour in the air will condense into water droplets on the surface of the equipment, which not only causes corrosion on the surface of the equipment, but also may affect the normal operation of the equipment. Insulation sleeve can improve the surface temperature of the equipment, so that it is higher than the dew point temperature, thereby reducing the occurrence of condensation.

?

?

Meet the requirements of environmental protection: through the installation of thermal insulation to reduce heat loss, help reduce energy consumption, and thus reduce the emission of pollutants due to energy production, in line with national and local environmental policies and requirements.

?

?

Insulation materials: different materials have different performance and durability. For example, the glass fibre insulation sleeve has better high temperature resistance and certain anti-aging ability, the service life is usually in 4-6 years; using our family's new nano-materials insulation sleeve, insulation performance is better, and wear-resistant, corrosion-resistant, the service life may reach 10 - 15 years.

Convenient disassembly and installation

Convenient to dismantle, easy to install, convenient to clean the pipeline equipment, convenient to repair and maintenance.

Convenient for regular inspection, maintenance and repair of the heat preservation sleeve, can find and deal with the damaged parts in time to extend its service life.

?

?

Cost saving

Can be used repeatedly, appearance and performance are not affected, can meet the needs of equipment maintenance, can be partially disassembled, and long service life, cost savings.

Tailor-made

Can be tailored according to the need for insulation parts, design, production and installation, and equipment, close fit, processing non-standard products.